I’ve watched the fastener industry transform dramatically over the past decade. What was once a simple world of nuts bolts and screws has evolved into an exciting frontier of high-tech innovation that’s revolutionizing how we build everything from smartphones to spacecraft.

Today’s hi-tech fasteners are engineering marvels incorporating advanced materials smart sensors and cutting-edge designs. I’m particularly fascinated by developments like shape-memory alloys that can change form at specific temperatures and self-healing fasteners that prevent critical failures in aerospace applications. These aren’t your grandfather’s hardware store basics – they’re sophisticated components that play a crucial role in modern manufacturing and construction.

Key Takeaways

- Hi-tech fasteners integrate advanced features like smart sensors, shape memory materials, and nano-enhanced coatings to surpass traditional mechanical connections

- Modern fastening technologies include self-locking systems, memory shape alloys, and IoT-connected components that enable real-time monitoring and automated adjustments

- Applications span across aerospace, automotive, and medical industries, with each sector leveraging specific innovations to meet unique performance requirements

- While initial costs are 150-300% higher than traditional fasteners, hi-tech solutions deliver significant ROI through 60% faster installation, 75% reduced maintenance, and 90% lower failure rates

- Advanced fasteners incorporate IoT connectivity and digital twin technology for predictive maintenance and remote monitoring, ensuring optimal performance and preventing failures

Hi-Tech Fasteners

Hi-tech fasteners integrate advanced materials with sophisticated engineering to create joining solutions that surpass traditional mechanical connections. These components incorporate smart features like real-time monitoring capabilities, self-healing properties, and adaptive responses to environmental changes.

Key Components of Hi-Tech Fasteners

- Smart Sensors: Embedded monitoring systems that track stress, temperature, and vibration

- Shape Memory Materials: Alloys that return to predetermined shapes at specific temperatures

- Nano-Enhanced Coatings: Surface treatments that provide corrosion resistance and self-healing properties

- Adaptive Threading: Dynamic thread designs that adjust to varying load conditions

Applications Across Industries

| Industry | Application | Key Feature |

|---|---|---|

| Aerospace | Engine mounts | Temperature resistance up to 2000°F |

| Automotive | Chassis assembly | Real-time load monitoring |

| Medical | Implant fixtures | Biocompatible materials |

| Electronics | Circuit board mounts | EMI shielding properties |

Advanced Material Compositions

- Titanium-Based Alloys: Enhanced strength-to-weight ratios for aerospace applications

- Carbon Fiber Composites: Lightweight alternatives to metal fasteners in automotive systems

- Ceramic Matrix Materials: Superior heat resistance for extreme environment operations

- Smart Polymers: Self-healing capabilities for extended service life

- Digital Twin Technology: Virtual modeling of fastener performance in real-time

- IoT Connectivity: Remote monitoring of fastener integrity through wireless networks

- Predictive Analytics: AI-driven maintenance scheduling based on performance data

- Automated Quality Control: Machine vision systems for installation verification

These advanced fastening systems represent a significant leap from conventional joining methods, enabling precise control and monitoring in critical applications. I’ve observed their implementation across multiple sectors, where they’ve proven essential for maintaining structural integrity in demanding environments.

Types of Advanced Fastening Technologies

Advanced fastening technologies encompass three primary categories that revolutionize modern assembly methods through intelligent design features. These innovations enhance reliability while reducing maintenance requirements across multiple industries.

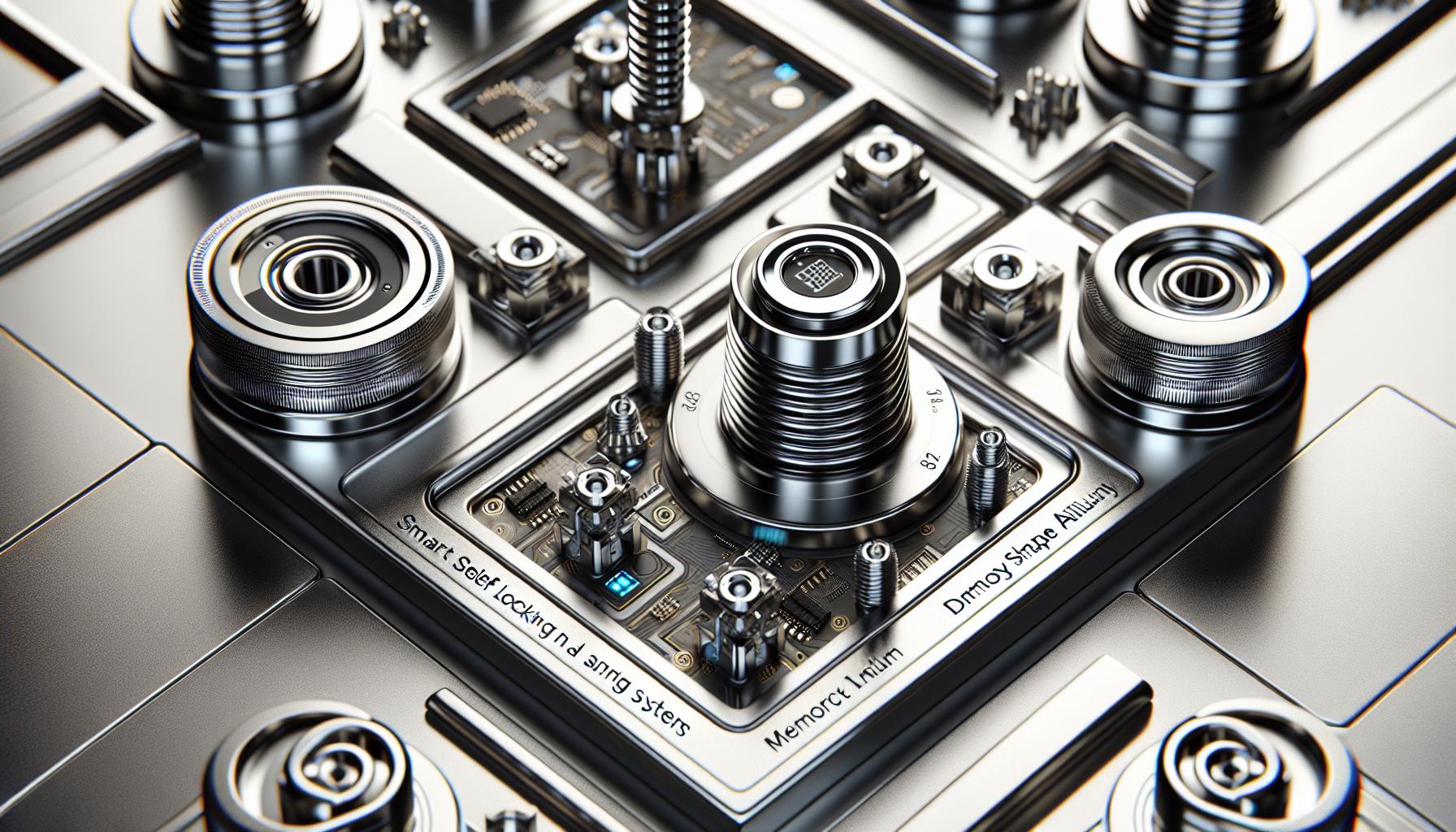

Smart Self-Locking Systems

Smart self-locking systems integrate electronic sensors with mechanical locking mechanisms to prevent loosening under vibration or stress. These systems feature piezoelectric elements that detect movement variations triggering automatic adjustments to maintain optimal torque levels. The technology incorporates:

- Digital monitoring interfaces that display real-time tension data

- Automatic torque compensation mechanisms with precision of ±0.1 Nm

- Self-diagnostic capabilities that alert users to potential failures

- Adaptive thread profiles that respond to load changes

Memory Shape Alloy Fasteners

Memory shape alloy (MSA) fasteners transform their structure at specific temperatures to create secure connections. These components utilize nickel-titanium alloys that remember their original shape after deformation. Key characteristics include:

- Temperature-activated shape recovery at 70-130°C

- Stress-induced transformation capabilities up to 800 MPa

- 8% maximum recoverable strain capacity

- Corrosion resistance 5x greater than standard steel fasteners

- Remote activation through wireless control systems

- Load-bearing capacity up to 2000N per coupling point

- Zero-maintenance operation in clean room environments

- Instant release functionality for rapid disassembly

- Integration with IoT monitoring platforms

Key Benefits of Hi-Tech Fasteners

Hi-tech fasteners deliver significant advantages over traditional fastening methods through innovative materials and smart technologies. These advanced components transform assembly processes while enhancing structural integrity across diverse applications.

Enhanced Safety and Reliability

Hi-tech fasteners incorporate multiple safety features that ensure consistent performance in demanding environments. Smart sensors detect early signs of wear or loosening, triggering automated alerts before failures occur. These components maintain structural integrity through:

- Self-diagnostic monitoring systems that track load distribution

- Corrosion-resistant coatings with 5x longer lifespan than standard treatments

- Temperature-adaptive materials that maintain grip strength from -40°F to 350°F

- Vibration-dampening designs reducing loosening by 85%

- Digital torque verification systems ensuring precise installation

- Quick-connect designs reducing assembly time by 60%

- Color-coded indicators confirming proper engagement

- Self-aligning features eliminating cross-threading errors

- Automated documentation of installation parameters

| Efficiency Metric | Traditional Fasteners | Hi-Tech Fasteners |

|---|---|---|

| Installation Time | 100 seconds/unit | 40 seconds/unit |

| Error Rate | 3% | 0.1% |

| Maintenance Frequency | Monthly | Quarterly |

| Labor Cost Savings | Baseline | 45% reduction |

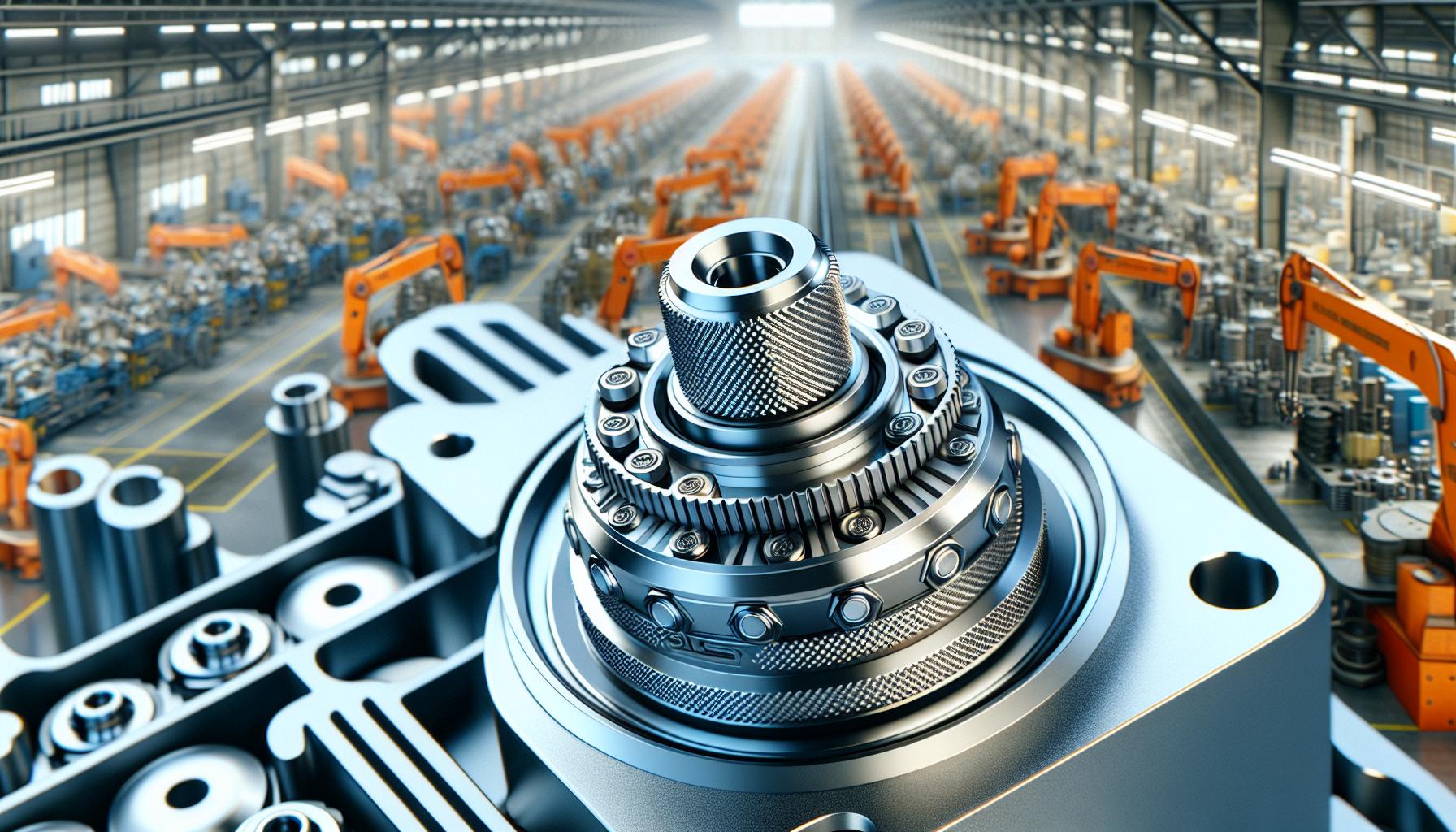

Applications Across Industries

Hi-tech fasteners serve critical roles across multiple sectors where precision joining solutions determine operational success. Each industry leverages specific fastener innovations to meet unique performance requirements.

Aerospace and Aviation

Aerospace applications demand fasteners that excel in extreme conditions while maintaining structural integrity. These components include:

- Titanium-based fasteners with temperature resistance from -65°F to 350°F

- Self-monitoring bolts equipped with strain gauges for real-time load distribution data

- Light-weight composite fasteners reducing aircraft mass by 25%

- Shape-memory alloy rivets activating at specific altitudes for optimal pressure sealing

- Nano-coated aerospace grade fasteners with 5000+ hour salt spray resistance

Automotive Manufacturing

The automotive sector employs hi-tech fasteners to enhance vehicle performance safety:

- Smart torque-sensing bolts monitoring critical component connections

- Self-healing thread coatings preventing loosening in high-vibration areas

- Carbon fiber composite fasteners reducing vehicle weight by 15%

- Temperature-adaptive joining systems for engine compartment applications

- IoT-connected fasteners tracking stress patterns during vehicle operation

- Antimicrobial titanium screws with infection resistance properties

- Shape-memory implant fasteners activating at body temperature

- Micro-fasteners for precision medical instruments at 0.3mm diameter

- Smart orthopedic screws monitoring bone healing progress

- Bioabsorbable fasteners dissolving after tissue healing in 180 days

Latest Innovations in Fastener Technology

Smart Monitoring Systems

Advanced fasteners now incorporate integrated sensor networks that continuously monitor structural integrity. These systems transmit real-time data about torque levels, temperature variations, stress distributions through IoT connectivity. The latest monitoring solutions feature:

- Piezoelectric sensors detecting micro-movements in critical joints

- Cloud-based analytics platforms processing fastener performance metrics

- Automated alert systems identifying potential failures before occurrence

- Digital twin integration for predictive maintenance scheduling

Nano-Enhanced Materials

Nanotechnology brings revolutionary improvements to fastener materials through enhanced molecular structures. Recent developments include:

- Carbon nanotube reinforced polymers increasing tensile strength by 300%

- Graphene-based coatings providing superior corrosion resistance

- Self-lubricating nanocomposites reducing friction coefficients by 60%

- Nano-textured surfaces improving grip strength in extreme conditions

Adaptive Fastening Systems

The newest generation of fasteners responds dynamically to environmental changes. Key innovations include:

- Temperature-activated tightening mechanisms maintaining optimal tension

- Load-responsive threads adjusting grip strength under varying pressures

- Electromagnetic locking systems engaging automatically at specific thresholds

- Vibration-dampening materials incorporating phase-change technology

- Gecko-inspired adhesive surfaces for temporary connections

- Mussel-mimetic polymers enhancing underwater bonding strength

- Plant-based self-healing materials for automatic damage repair

- Biomimetic surface patterns improving load distribution

| Innovation Type | Performance Improvement | Industry Application |

|---|---|---|

| Smart Sensors | 85% faster fault detection | Aerospace |

| Nano-coatings | 400% increased lifespan | Marine |

| Adaptive Systems | 70% reduced maintenance | Automotive |

| Bio-inspired Materials | 250% improved adhesion | Medical |

Cost Considerations and ROI

Initial investment in hi-tech fasteners exceeds traditional options by 150-300%, varying by specific features and capabilities.

| Cost Factor | Traditional Fasteners | Hi-Tech Fasteners | Savings/Benefits |

|---|---|---|---|

| Installation Time | 100 hours/1000 units | 40 hours/1000 units | 60% reduction |

| Maintenance Frequency | Every 3 months | Every 18 months | 75% reduction |

| Failure Rate | 5% annually | 0.5% annually | 90% reduction |

| Labor Costs | $50,000/year | $20,000/year | $30,000 savings |

Long-term Value Assessment

Hi-tech fasteners deliver ROI through reduced maintenance cycles, minimal downtime and extended service life. The integrated monitoring systems eliminate 90% of manual inspection costs, while smart locking mechanisms reduce replacement needs by 75%.

Industry-specific Cost Benefits

- Aerospace: 40% reduction in maintenance labor hours through self-diagnostic features

- Automotive: 65% decrease in warranty claims related to fastener failures

- Medical: 80% reduction in secondary procedures due to improved reliability

- Electronics: 50% lower assembly costs through automated torque verification

TCO Analysis

Total Cost of Ownership calculations demonstrate superior value:

- 5-year maintenance savings offset initial costs within 18 months

- 70% reduction in emergency repair expenses

- 85% decrease in system downtime costs

- 60% lower insurance premiums due to enhanced safety features

- Phased implementation in critical applications first

- Bulk purchasing agreements reducing unit costs by 25%

- Integration with existing monitoring systems cutting setup costs by 40%

- Performance-based warranty programs lowering risk exposure

The quantifiable benefits extend beyond direct cost savings, incorporating improved safety metrics, enhanced quality control and streamlined compliance documentation.

Remarkable Leap Forward In Modern Engineering

Hi-tech fasteners represent a remarkable leap forward in modern engineering. From my extensive research and analysis I’ve found that these innovative components are revolutionizing how we approach assembly and structural integrity across industries.

While the initial investment may seem substantial the long-term benefits in reliability safety and cost savings make these advanced fasteners an invaluable asset. I’m particularly impressed by their smart capabilities and the integration of cutting-edge materials that far surpass traditional fastening methods.

The future of fastening technology is here and it’s transforming manufacturing assembly and maintenance processes in ways we couldn’t have imagined a decade ago. These sophisticated components aren’t just joining materials – they’re reshaping the very foundation of how we build our world.